Layer Height and

Nozzle Width References

Understanding Layer Height and Nozzle Width for 3D Printing

When it comes to 3D printing, the details matter. Two crucial factors that significantly impact the quality and precision of your 3D prints are the layer height and the nozzle width.

Layer Height:

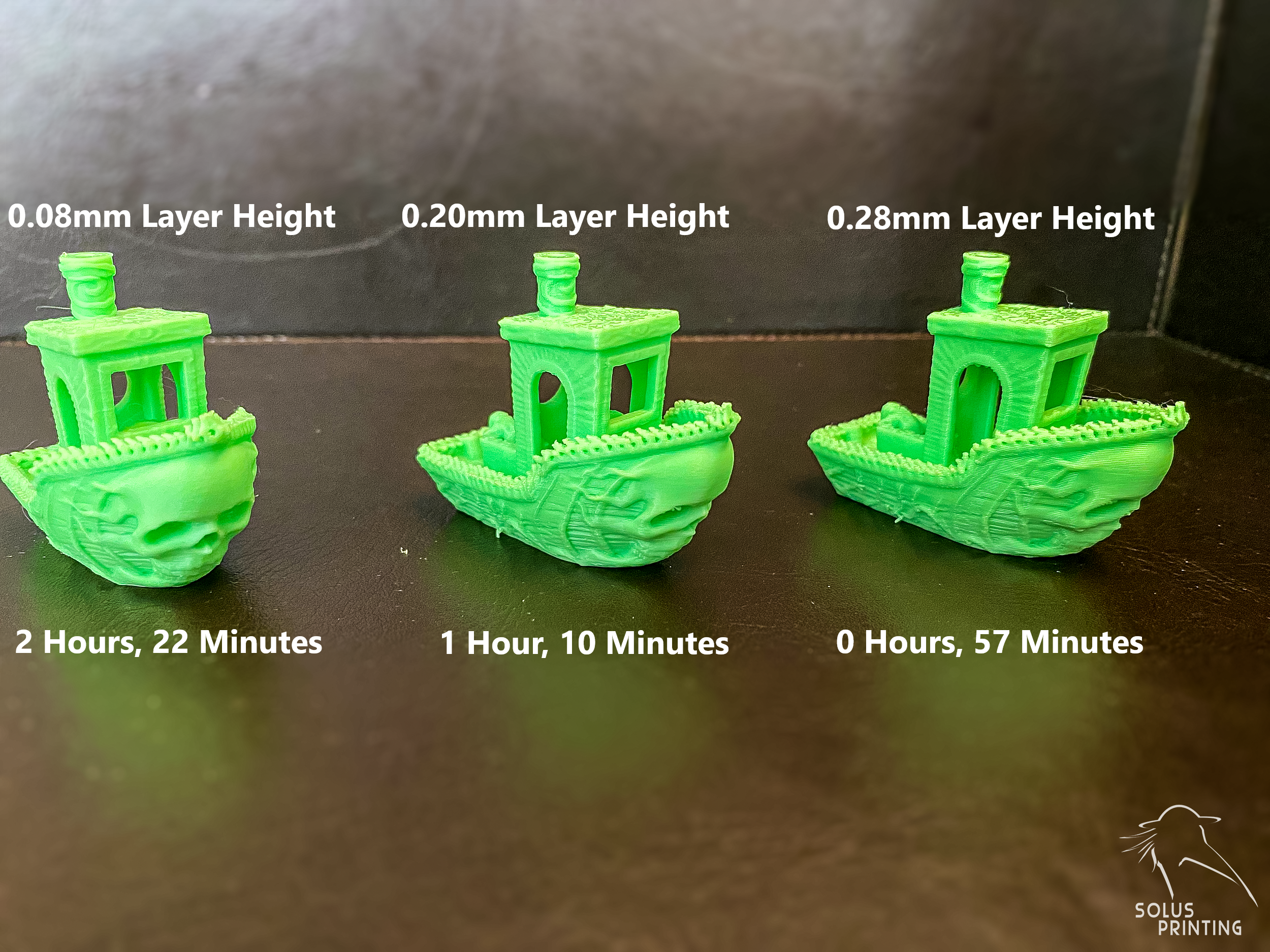

The layer height refers to the vertical thickness of each layer that the 3D printer deposits to create an object. Choosing the right layer height is critical as it greatly influences the surface finish and overall resolution of the printed object. A smaller layer height produces finer details and smoother surfaces, while a larger layer height can result in visible layer lines and decreased detail.

Nozzle Width:

The nozzle width determines the size of the extruded filament and, consequently, the level of detail that can be achieved. A smaller nozzle width allows for finer details and intricate designs, while a larger nozzle is more suitable for rapid prototyping and larger, less detailed prints.

Why It Matters:

Understanding the relationship between layer height and nozzle width empowers you to optimize your 3D printing projects. By selecting the appropriate settings for your specific needs, you can achieve the level of detail and surface finish required for your designs. This knowledge also allows you to balance print time and quality, as smaller layer heights and nozzles typically result in longer print times.

In conclusion, being knowledgeable about layer height and nozzle width is crucial for harnessing the full potential of 3D printing. It enables you to make informed decisions that result in precise, high-quality prints tailored to your unique requirements.

The model used for these comparisons was created by spooner2011

These models were all printed on the same printer using the same PLA. They all used 2 walls, 2 top and bottom layers, the same build plate, the same speed and 15% grid infill. The only variation is the nozzle width and the layer height.

These models were printed using a 0.8mm nozzle. Fine detail is dramatically lost, however the time it takes to print is reduced just as dramatically. This is more useful for simple shapes and low-precision printing.

These models were printed using a 0.2mm nozzle. This is good for smaller, detailed prints that require the highest accuracy. The side effect is that it cannot be used for filaments that contain reinforcements or particulates and makes for a much longer printing time.

These models were printed using a 0.4mm nozzle. This is the standard for printing. Useable with almost all types of filament it is the balance between speed and precision. This nozzle at 0.20mm layer height is the standard definition for printing.